Aluminum Alloy Automotive End Plates

Product Introduction

1. Lightweight Construction: Aluminum alloy end plates are renowned for their lightweight properties, contributing to overall vehicle weight reduction. This feature enhances fuel efficiency and lowers emissions, aligning with modern automotive industry trends toward sustainability.

2. Corrosion Resistance: Aluminum alloys possess excellent corrosion resistance properties, ensuring durability and longevity in harsh environmental conditions. This characteristic prolongs the lifespan of automotive end plates, enhancing the vehicle's reliability and reducing maintenance requirements.

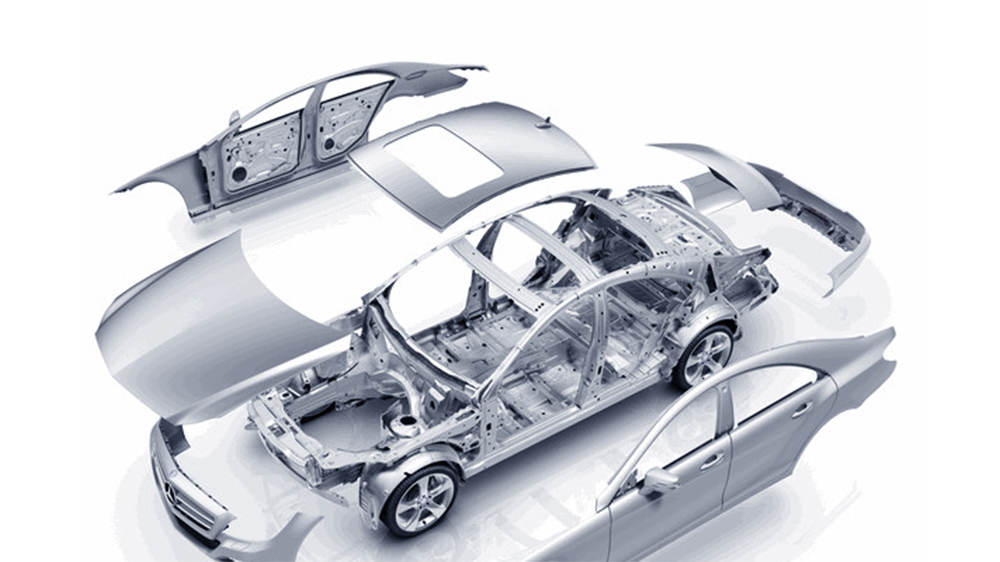

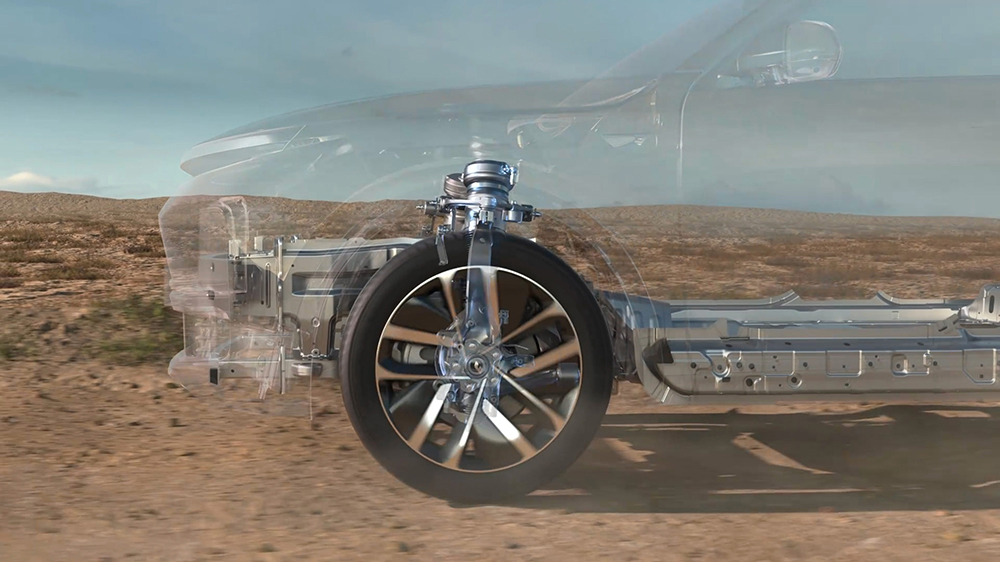

3. Enhanced Performance: The use of aluminum alloy end plates contributes to improved vehicle performance by reducing unsprung mass, enhancing handling, and optimizing suspension dynamics. These end plates also provide structural rigidity, enhancing chassis stiffness and overall driving dynamics.

4. Design Flexibility: Aluminum alloys offer design flexibility, allowing for the creation of complex shapes and intricate designs to meet specific automotive requirements. This flexibility enables automotive manufacturers to optimize end plate designs for aerodynamic efficiency, thermal management, and aesthetic appeal.

5. Recyclability: Aluminum alloys are highly recyclable materials, aligning with the automotive industry's sustainability goals. The recyclability of aluminum end plates reduces environmental impact and promotes resource conservation, making them an eco-friendly choice for automotive applications.

6. Cost-Effectiveness: Despite their superior properties, aluminum alloy end plates offer cost-effectiveness compared to alternative materials. Their lightweight nature reduces transportation costs and fuel consumption, while their durability minimizes maintenance and replacement expenses, providing long-term cost savings for automotive manufacturers and consumers alike.

Application

Aluminum alloy automotive end plates are essential components widely used in the automotive industry. These end plates are strategically positioned at the ends of various automotive systems, such as radiators, intercoolers, and condensers. Their primary function is to provide structural support and sealing for these systems, ensuring efficient operation and optimal performance of the vehicle.

In addition to structural support, aluminum alloy end plates play a crucial role in heat dissipation and thermal management within the vehicle. They are designed to dissipate heat generated by the engine and other components, helping to maintain optimal operating temperatures and prevent overheating. This is particularly important in high-performance vehicles and those operating in demanding conditions, such as racing cars and heavy-duty trucks.

Furthermore, aluminum alloy end plates offer several advantages over traditional materials like steel or plastic. They are lightweight, which helps to reduce the overall weight of the vehicle and improve fuel efficiency. They also exhibit excellent corrosion resistance, ensuring long-term durability even in harsh environmental conditions.

Overall, aluminum alloy automotive end plates are vital components that contribute to the performance, efficiency, and reliability of modern vehicles. Their widespread use across various automotive systems underscores their importance in the automotive industry.

Parameter

| Extrusion Line: | 12 extrusion lines and monthly output can reach 5000 tons. | |

| Production Line: | 5 production line for CNC | |

| Product Capacity: | Anodizing Electrophoresis monthly output is 2000 tons. | |

| Powder Coating monthly output is 2000 tons. | ||

| Wood Grain monthly output is 1000 tons. | ||

| Alloy: | 6063/6061/6005/6060/7005. (Special alloy could be made upon your requirements.) | |

| Temper : | T3-T8 | |

| Standard: | China GB high precision standard. | |

| Thickness: | Based on your requirements. | |

| Length: | 3-6 M or customized length. And we can produce any length you want. | |

| MOQ: | Normally 2 tons. Usually 15-17 tons for 1*20GP and 23-27 tons for 1*40HQ. | |

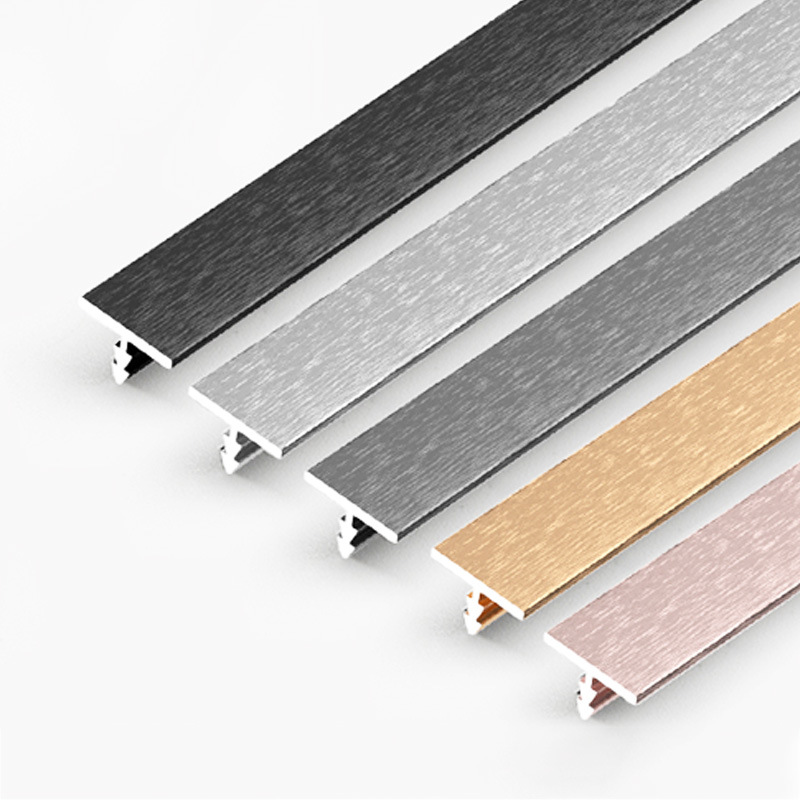

| Surface Finish: | Mill finish, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. | |

| Color We Can Do: | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized. | |

| Film Thickness: | Anodized: | Customized. Normal thickness: 8 um-25um. |

| Powder Coating: | Customized. Normal thickness: 60-120 um. | |

| Electrophoresis Complex Film: | Normal thickness: 16 um. | |

| Wood Grain: | Customized. Normal thickness: 60-120 um. | |

| Wood Grain Material: | a). Imported Italian MENPHIS transfer printing paper. b). High quality China transfer printing paper brand. c). Different prices. | |

| Chemical Composition & Performance: | Meet and execution by the China GB high precision level. | |

| Machining: | Cutting, punching, drilling, bending, weld, mill, CNC, etc. | |

| Packing: | Plastic film & Kraft paper. Protect film for each piece of profile is also ok if required. | |

| FOB Port: | Foshan,Guangzhou,Shenzhen. | |

| OEM: | Available. | |

Samples

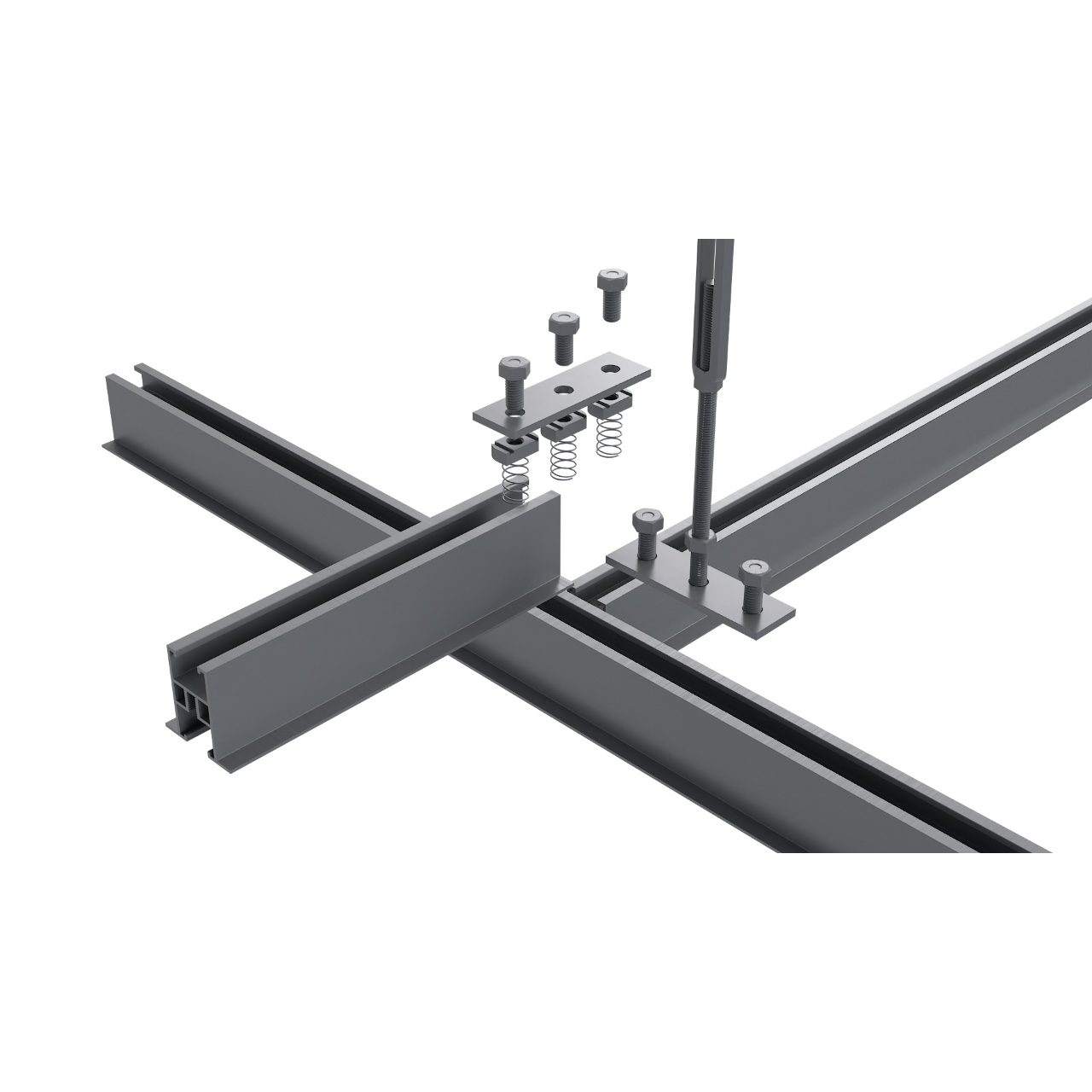

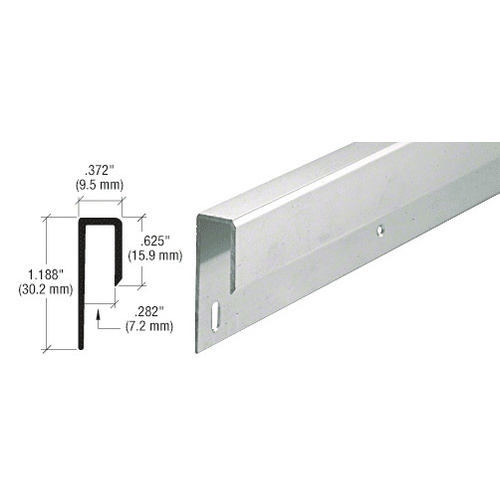

Structures

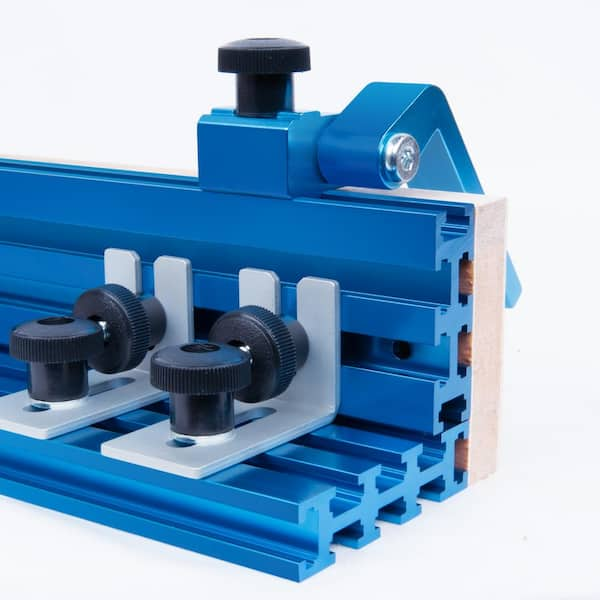

Details

| Place of Origin | Guangdong, China |

| Delivery Time | 15-21 days |

| Temper | T3-T8 |

| Application | industrial or construction |

| Shape | customized |

| Alloy Or Not | Is Alloy |

| Model Number | 6061/6063 |

| Brand Name | Xingqiu |

| Processing Service | Bending, Welding, Punching, Cutting |

| Product name | aluminum extruded profile for fence |

| Surface treatment | Anodize,Powder coat,Polish,Brush,Electrophresis or customized. |

| Color | many colors as your choice |

| Material | Alloy 6063/6061/6005/6082/6463 T5/T6 |

| Service | OEM & ODM |

| Certification | CE,ROHS, ISO9001 |

| Type | 100% QC Testing |

| Length | 3-6meters or Custom Length |

| Deep processing | cutting, drilling, threading, bending, etc |

| Business type | factory, manufacturer |

FAQ

-

Q1. what’s your MOQ ? And what is your delivery time?

-

Q2. If I need sample, could you support?

+A2. We can provide you free samples for check our quality, but the delivery fee should be paid by our customer, and it is appreciated could send us your International Express Account For Freight Collect.

-

Q3. How do you charge mould fees?

+ -

Q4. What is the differences between theoretical weight and actual weight?

+ -

Q5. What’s your payment term?

+ -

Q6 Could you provide OEM &ODM services?

+ -

Q7. How can you guarantee the quality?

+